- Ford kondigt een extra investering in Solid Power aan, voor de verdere ontwikkeling van solid-state accutechnologie voor auto’s. Het doel is klanten een grotere actieradius en veiligere elektrische voertuigen te bieden tegen lagere kosten

- Deze investering bouwt voort op de investering die Ford in 2019 deed en vergroot het strategische aandeel van Ford in het partnerschap om solid-state batterijcellen en arrays te testen en op te schalen en hun beschikbaarheid in toekomstige EV’s van Ford te helpen versnellen

- Met deze investeringsronde hebben Ford en BMW Group ieder een gelijk aandeel in Solid Power. Vertegenwoordigers van beide autofabrikanten treden toe tot de raad van bestuur van Solid Power

- Beide autofabrikanten hebben elk ook afzonderlijke overeenkomsten met Solid Power voor het ontwikkelen en testen van batterijtechnologie, zodat zij ieder voor zich kunnen voldoen aan hun eigen eisen op het gebied van ontwikkeling en productie van nieuwe voertuigen

- Fords nieuwste investering in Solid Power komt bovenop de eerder aangekondigde wereldwijde investering van 22 miljard dollar in geëlektrificeerde en verbonden voertuigen tot en met 2025. Het bouwt voort op Fords aankondiging van afgelopen dinsdag dat het een nieuw wereldwijd batterij-expertisecentrum creëert

Ford Motor Company heeft aangekondigd dat het zijn investering in Solid Power, de toonaangevende producent van solid-state accu’s voor elektrische auto’s, verhoogt. Lees verder

Downloads

Ford investeerde in 2019 al in Solid Power en doet nu een extra investering om de verdere ontwikkeling van solid-state accutechnologie voor auto’s te helpen versnellen. Dit gebeurt in het kader van een zogenoemde Serie B-investeringsronde van 130 miljoen dollar, waarmee Ford en BMW Group gelijkwaardige aandeelhouder worden.

“Solid-state accutechnologie is belangrijk voor de toekomst van elektrische voertuigen en daarom investeren we er direct in en versnellen Fords interne R&D op het gebied van de volgende generatie accutechnologie”, aldus Hau Thai-Tang, Chief Product Platform and Operations Officer van Ford. “Gebruikmakend van de snelheid van een startup en de expertise van enkele van onze meest doorgewinterde accu-experts ter wereld, onderzoeken we manieren om de volledig elektrische voertuigen van de toekomst van stroom te voorzien en rijplezier te laten bieden, met behulp van ontwikkelings- en productieprocessen die zich al hebben bewezen.”

Solid-state accu’s zijn veelbelovend. Ze zijn niet voorzien van de vloeibare elektrolyt, die wel wordt toegepast in conventionele lithium-ion-accu’s, en kunnen daardoor lichter zijn en een grotere energiedichtheid en een grotere actieradius bieden, tegen lagere kosten.

Lees het bericht hieronder verder in het Engels:

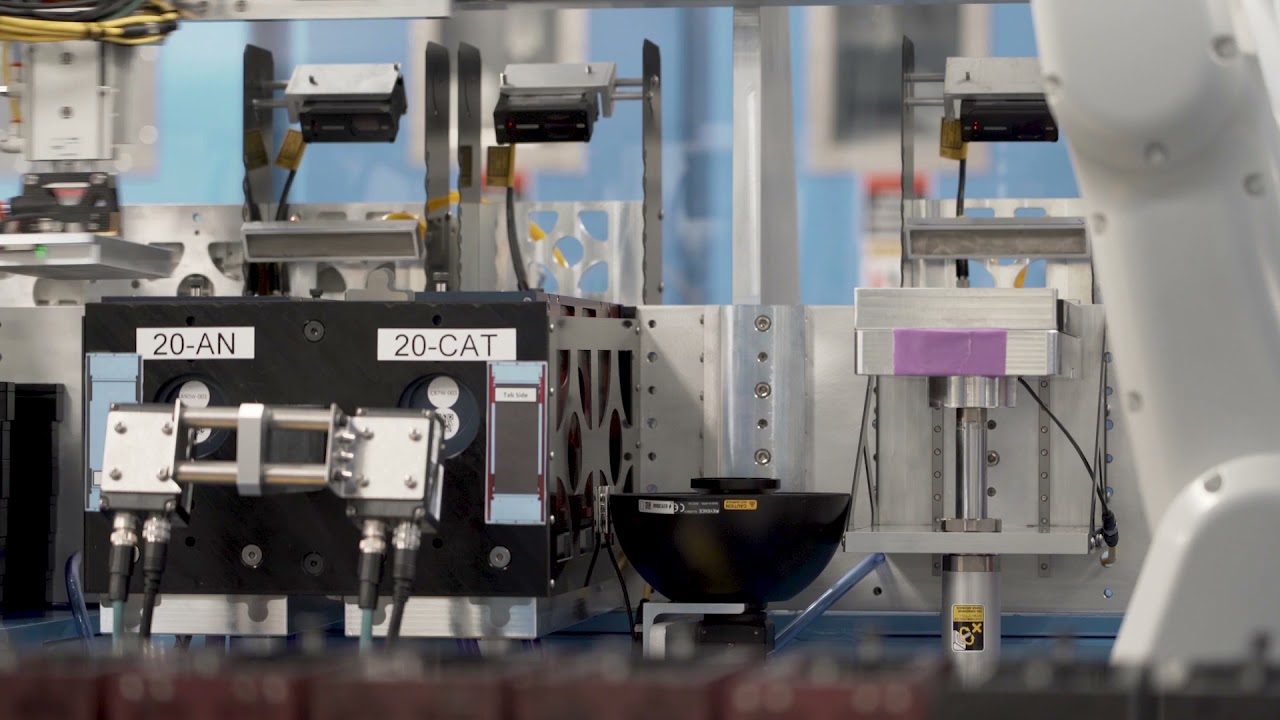

Solid Power, which uses sulfide-based solid-state battery cells, has demonstrated its ability to produce and scale next-generation all solid-state batteries that are designed to power longer range, lower cost and safer electric vehicles using existing lithium-ion battery manufacturing infrastructure.

Solid Power’s leadership in all solid-state battery development and manufacturing has been confirmed with the delivery of hundreds of production line-produced battery cells that were validated by the BMW Group and Ford late last year, formalizing Solid Power’s commercialization plans with its two long-standing automotive partners.

“By simplifying the design of solid-state versus lithium-ion batteries, we’ll be able to increase vehicle range, improve interior space and cargo volume and ultimately deliver lower costs and better value for customers,” said Ted Miller, Ford’s manager of electrification subsystems and power supply research. “We look forward to delivering these improvements and working with Solid Power to seamlessly and quickly integrate their sulfide-based all-solid-state battery cells into existing lithium-ion cell production processes more efficiently than oxide-based solid-state battery cell makers can.”

Under the new agreement, Ford will receive full-scale 100 ampere hour (Ah) cells from Solid Power for testing and integration into its future vehicles starting next year. Solid Power already is producing 20 Ah solid-state batteries on a pilot manufacturing line using lithium-ion production processes and equipment.

Ford also has a separate joint development agreement with Solid Power to develop and test its specific battery cell design and help streamline Ford’s integration into future vehicles.

Ford Building EV, Battery Tech Momentum

Earlier this week, Ford announced a new global battery center of excellence – named Ford Ion Park – to accelerate research and development of its battery and battery cell technology – including future battery manufacturing.

Ford is building on nearly two decades of battery expertise by centralizing a cross-functional team of 150 experts in battery technology development, research, manufacturing, planning, purchasing, quality and finance to help Ford more quickly develop and manufacture battery cells and batteries, ultimately aiming to deliver more, even better, lower cost EVs for customers.

The Ford Ion Park team also is exploring better integration and innovation opportunities across all aspects of the value chain – from mines to recycling – working with all teams within Ford, including experts at Ford’s new Battery Benchmarking and Test Laboratory, Ford Customer Service Division, plus key suppliers and partners.

The Ford Ion Park team already is underway. In addition, a $185 million collaborative learning lab in Southeast Michigan that is dedicated to developing, testing and building vehicle battery cells and cell arrays opens late next year.

This world-class 200,000 sq.-ft. learning lab will include pilot-scale equipment for electrode, cell and array design and manufacturing and will use state-of-the-art technology to pilot new manufacturing techniques that will allow Ford to quickly scale breakthrough battery cell designs with novel materials once the company vertically integrates battery cells and batteries.

Committed to leading the EV revolution

Ford is committed to leading the electric vehicle revolution and this year has gained significant momentum on its plans.

In North America, the Ford Mustang Mach-E has found early sales success. Plus, the all-electric Ford Transit is set to go on sale late this year and the all-electric F-150 arrives by mid-2022. Ford will be the first automaker in the U.S. to offer commercial customers fully electric van and full-size pickup choices.

In Europe, Ford is moving to an all-electric lineup by 2030, with its commercial vehicle range 100 percent zero-emissions capable, all-electric or plug-in hybrid by 2024. Ford also is investing $1 billion in a new electric vehicle manufacturing center in Cologne to build a high-volume all-electric passenger vehicle for European customers starting in 2023.

In China, Ford is preparing to produce the Mustang Mach-E for local customers later this year, and recently announced it is establishing a BEV division with a direct sales model and network that will reach 20 major cities across China this year. In addition, Ford has partnered with China’s State Grid and NIO to offer EV customers access to more than 300,000 public charging stations, of which 160,000 are fast-charging, in more than 340 cities across the country.

Proven electrification expertise

Ford has been actively involved in battery research and electric vehicles dating back to the days of Henry Ford and Thomas Edison. To date, the company has secured more than 2,500 U.S. patents in electrification technologies, with another 4,300 patents pending and has sold more than 1 million hybrids, plug-in hybrids and all-electric vehicles since 2004.